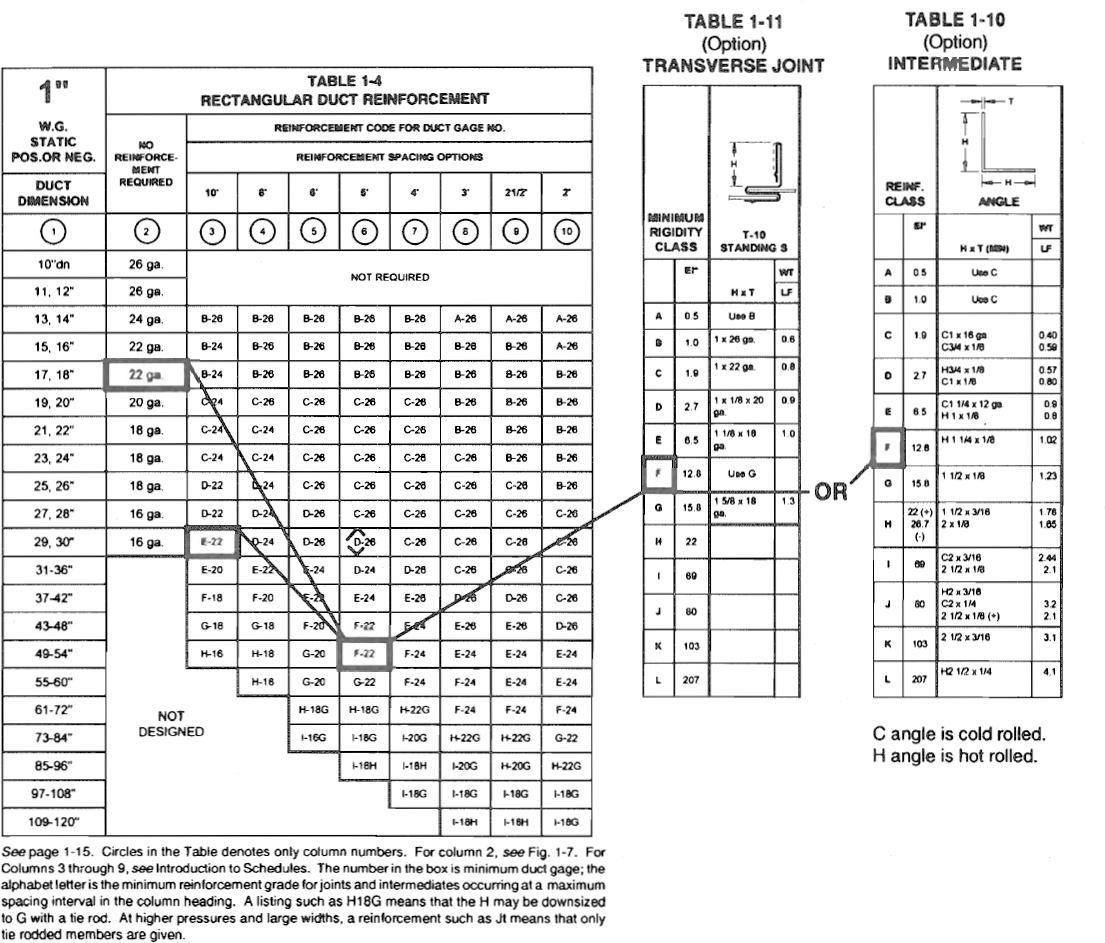

Minimum Sheet Metal Thickness Tapping

If we multiply the 050 by 2 we arrive at a wall thickness of 100.

Minimum sheet metal thickness tapping. 1 factors determining the minimum l bending. It shall be equal to three times of sheet thickness plus bend radius. We ll cover the common groups. Over time though different types evolved.

The minimum distance between two counterbores is eight times the material thickness. Thread forming thread cutting thread rolling and self drilling. For limited material thickness you can decrease the drilling and tapping depths and do one or more of following and still accommodate the full insert length and set it below the. The general rule of thumb is to have a wall thickness that is two times the pitch of the tap.

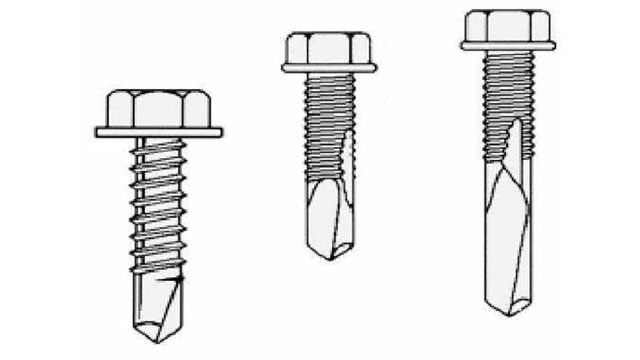

Determining wall thickness with metric taps is even more straight forward. Minimum sheet metal thickness for tapping. And break off when they contact metal surface minimum metal thickness 0 06 to be drilled. View profile view forum posts visit homepage.

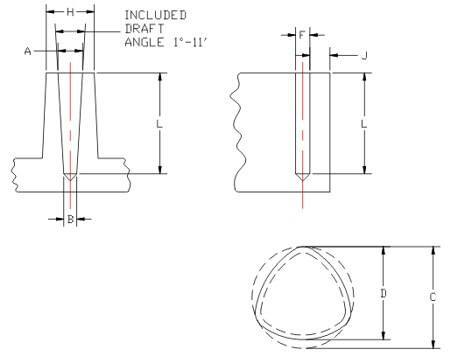

11 17 2009 11 35 am 2. Minimum sheet metal flange bend length is required to avoid cracks in the bending area. The minimum full thread tapping depth h for through and blind holes without a countersink is equal to the insert nominal length ln. The minimum bend edge dimension l in the figure is the minimum bend edge dimension of one bend edge plus t t is the material thickness and the height h should be selected from commonly used plates such as 0 5 0 8 1 0 1 2 1 5 2 0.

Minimum sheet metal flange bend length 3 x sheet thickness bend radius. For example tapping standoff threads into a motherboard tray. In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger counterbores. Avoid large sheet metal parts with small bent flanges.

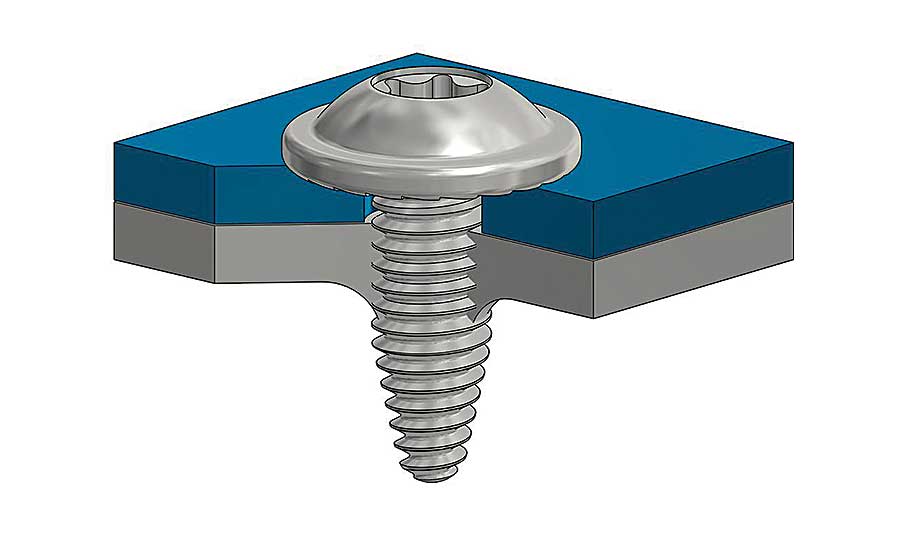

Tapping screws especially type a are referred to as sheet metal screws because one of their first applications was in ventilation ducts made of sheet metal. 1 factors determining the minimum l bending. For example if a 20 tap is required each thread pitch of a 20 thread per inch tap is 050. I m guessing 2mm but would 1 5mm suffice.

Point length winged drill reamer flute drilling capacity material thickness recommendations steel to steel thickness of material to be drilled in 0 500 2 point 3 point 4 point 5 point 0 500 0 400 0 300 0 200 0 210 0 220 0 250 0 250 0 250 0.