Minimum Bending Radius Copper Sheet

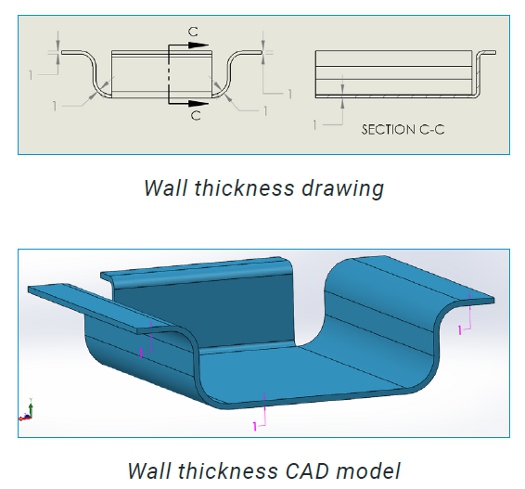

Let s say i have a 2 mm thick sheet and i want to bend it.

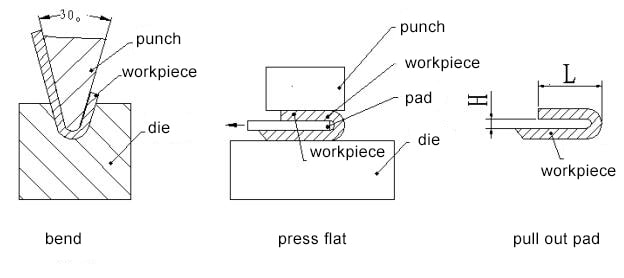

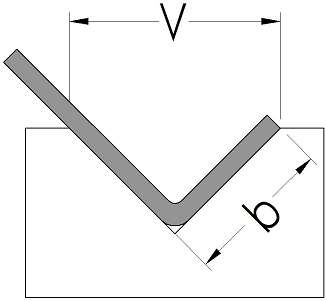

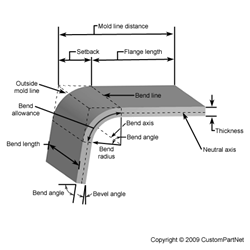

Minimum bending radius copper sheet. To keep it simple i also use a 2 mm inside radius. Radii for various thicknesses expressed in terms of thickness t. Tube and pipe bending. The minimum bend radius data shown in these charts is measured to the inside of the bend.

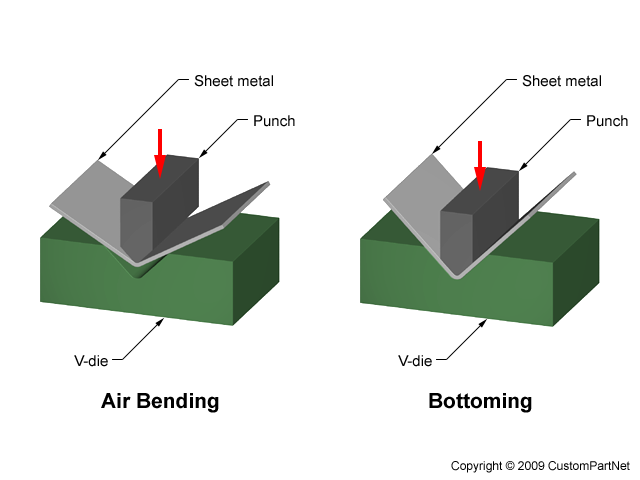

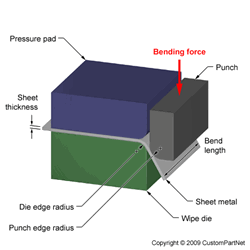

Bend radius is the minimum radius a pipe cable wire sheet cable tube or hose can bend without damaging it including kinking. The minimum bend radius is the radius below which an object should not be bent. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. For steel the factor is 1.

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. In steel between 0 5 and 0 8 in. C opper and coppe r alloy bar can be bent using standard bending methods. For example the minimum bending radius of aluminium is determined by multiplying the sheet thickness by a factor of 2.

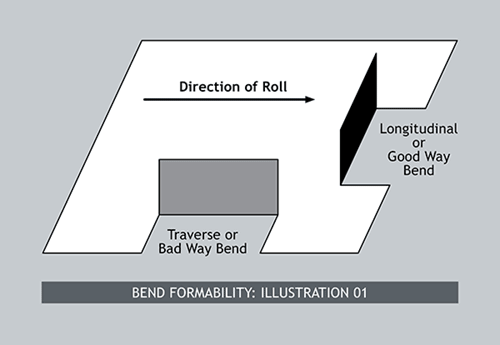

Aluminum minimum bend radii for 90 degree cold forming of sheet and plate. The first uses bending springs and the second a. Most copper pipe tube can be readily bent and two main methods are employed. Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness see figure 1.

Material bend radii and minimum bend size charts please note. If copper has to be bent a factor of 1 5 must be used. What is bending radius and minimum bending radius. As a general rule the minimum bending radius for copper bar is equal to the thickness of the bar.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. Per the aluminum association inc. For ordinary low carbon steel plate anti rust aluminum plate yellow copper purple copper etc the inner radius 0 2 is no problem but for some high carbon steel hard aluminum super hard aluminum the use 0 2 radius will lead to bending fracture or the outer radius crack. The smaller the radius the greater is the flexibility of the material.

I can now see that the minimum flange length is 8 5 mm for such a bend so i have to keep it in mind when designing. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.

You can check full details in this post.