Minimum Bend Radius For Sheet Metal Parts

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

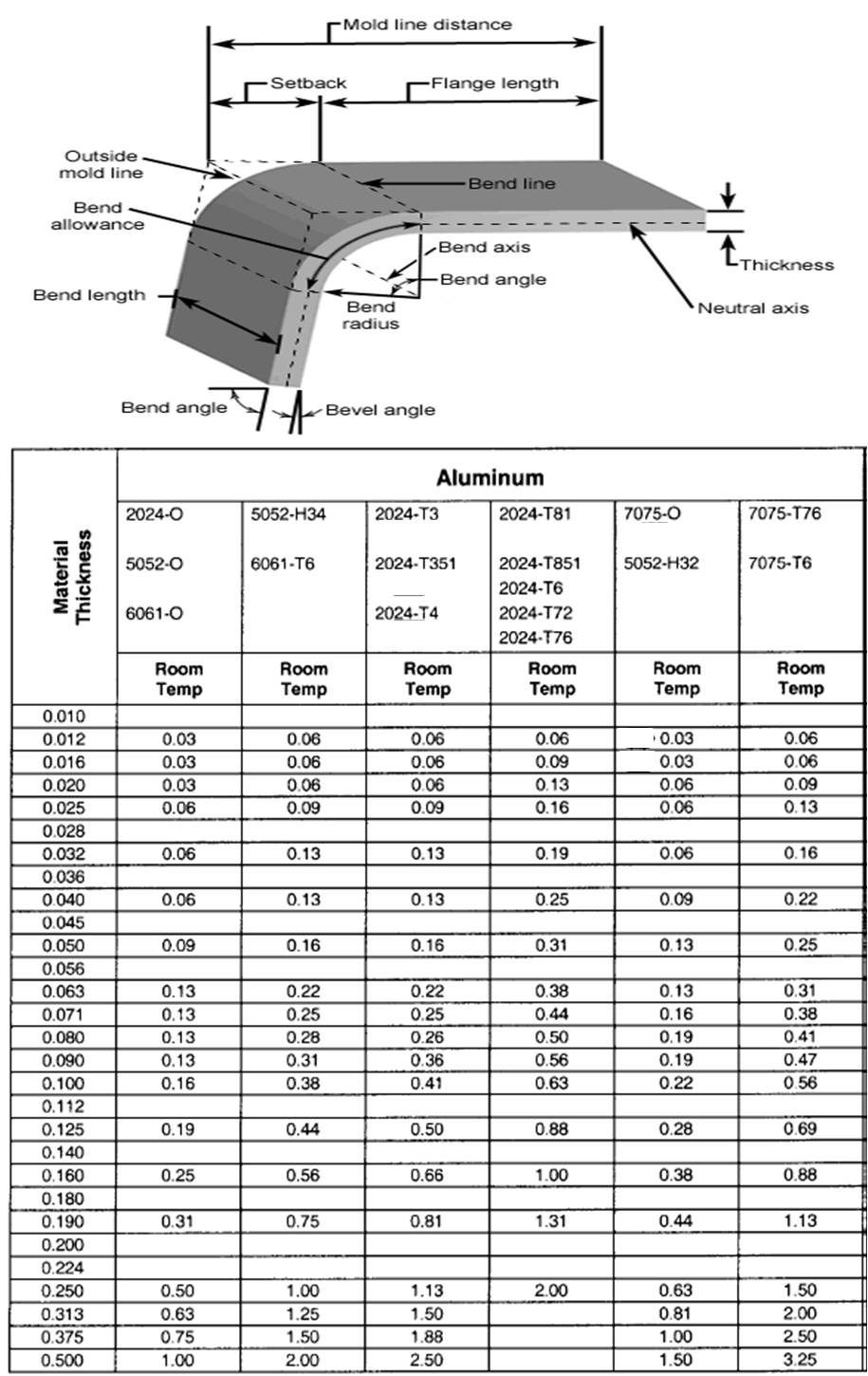

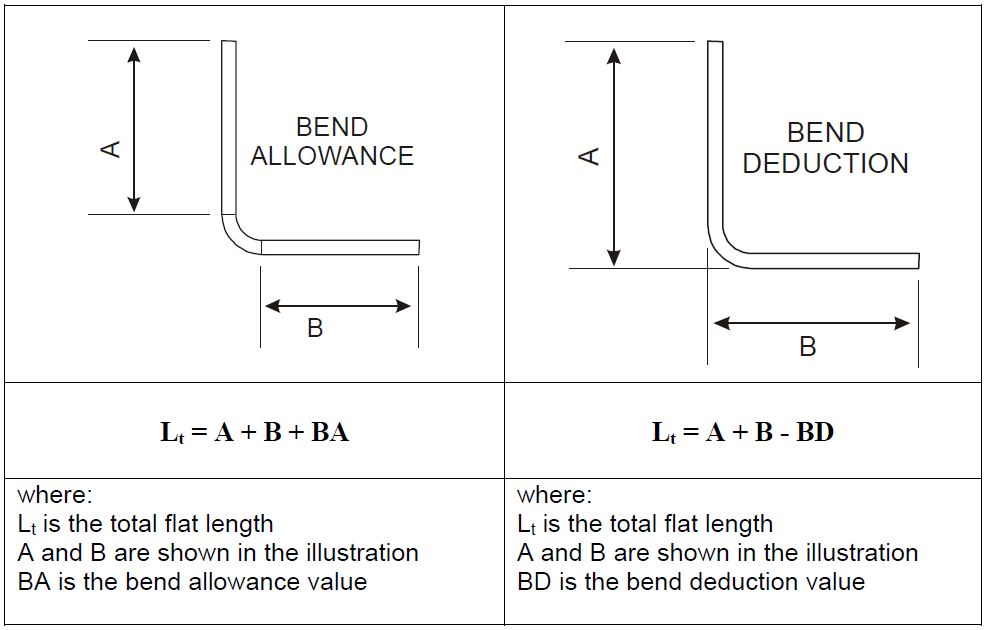

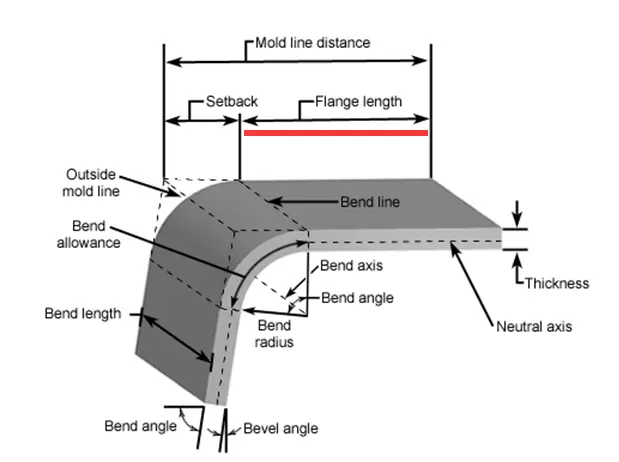

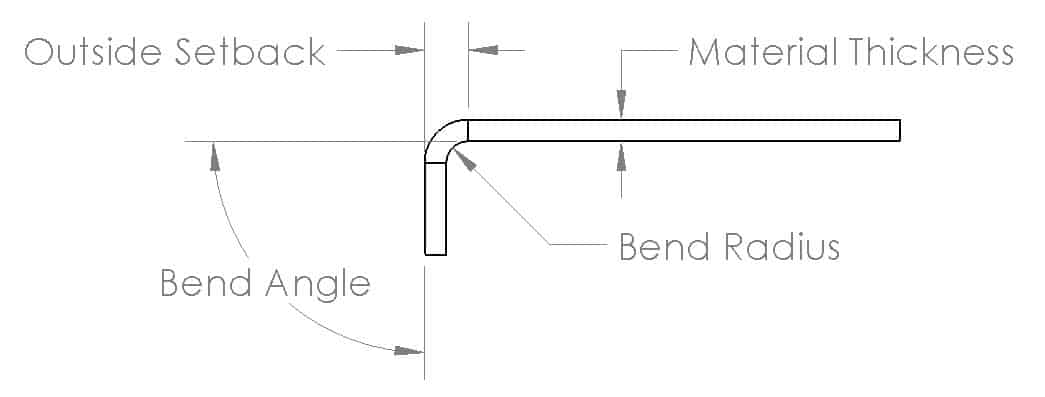

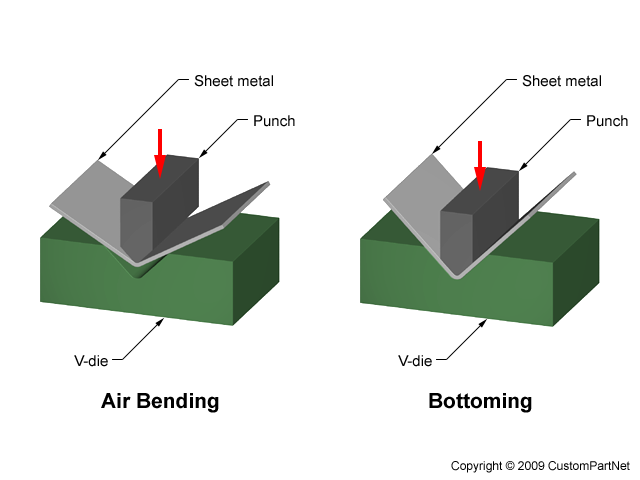

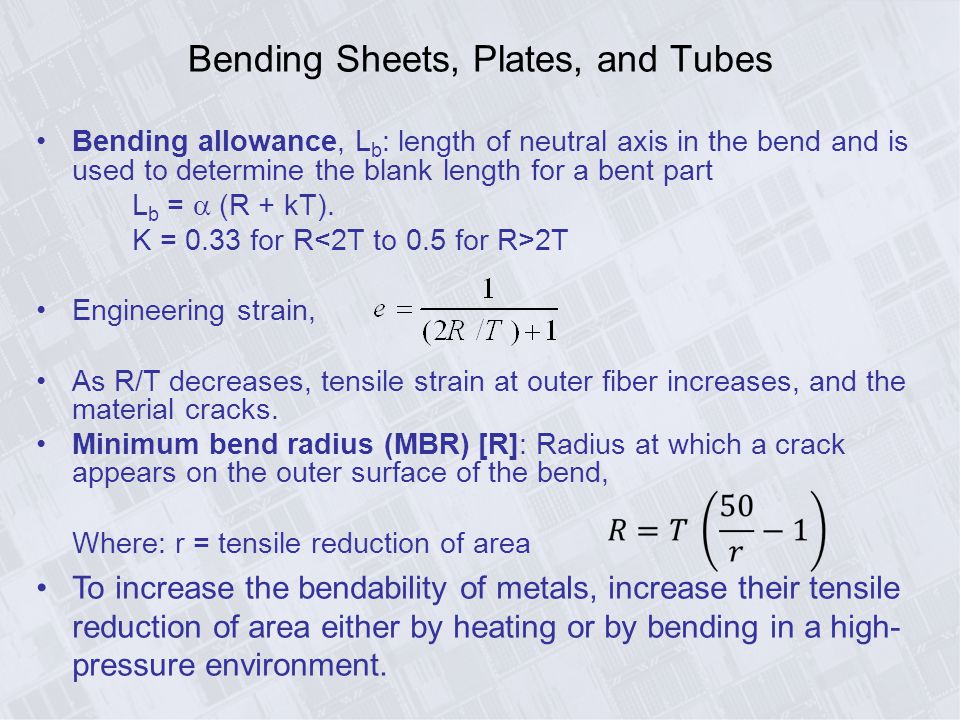

Minimum bend radius for sheet metal parts. Height of arc 2 material thickness 2 inside radius 0 201 2 0 01562 inside bend radius 0 201 0 031 0 170 in. Bends in sheet metal are manufactured using sheet metal brakes. If a piece of material is bent too tightly problems can occur. Supplying 3d models without considering these factors increases the chance.

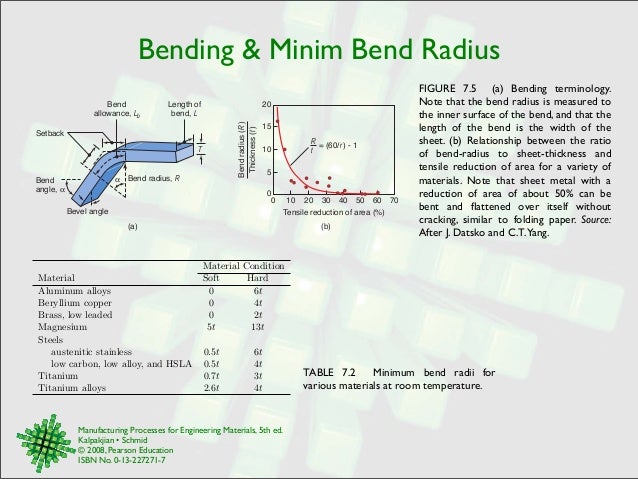

Below is xometry s minimum bend radius reference table which is based on. Upon close examination of the bends we find that the sheet metal stretches on the outer surface and that the inside surface seems to shrink. A 1 degree tolerance on all bend angles. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Hi can anyone tell me what the minimum bend radius for ss probably 303 304 and 6061 t6 al is. Now we take the height of arc value for our new bend angle and we plug it into the following formula. We recommend a minimum bend radius of 1t for all sheet metal parts. Layout method sheet metal stretches when it bends is an oversimplification.

Usually the preferred distance between holes and a bend is 1 5 times the sheet thickness plus the bend radius 1 5t h. Height of arc outside bend radius. Recommended inside bend radius for sheet metal parts should be equal to material thickness. It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

For bent sheet metal variation in the raw material thickness increases the recommended precision to 0 010 in. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. Each and every bend in a piece of sheet metal has a certain minimum internal radius that needs to be taken into account when planning the design of a sheet metal form. Posted by product design engineer on november 23 2009 at 1 55pm in mechanical engineering.

But for harder materials e g. Bend radii minimum bend sizes. The problem with bending too tightly. For example if the thickness of the sheet is 1 mm the minimum bend radius should be 1 mm.

When designing sheet metal parts and enclosures it is helpful to use these values as the basis for your design. Crca inside bend radius equal to 0 65 times of sheet thickness is also enough. Bend radii and minimum bends are limited to certain values or ranges which are determined by the equipment and tooling combinations available to the manufacturer. Minimum bend radius for sheet metal parts.